Audion Vacuum Chambers

From: £1,595.00

- Ideal for producing compact packs that offer protection from air and moisture

- Choice of desktop and free-standing models

- All operated via a digital control panel for simple operation

- Varying pump capacity to suit your operation

- Designed for use with our range of vacuum pouches

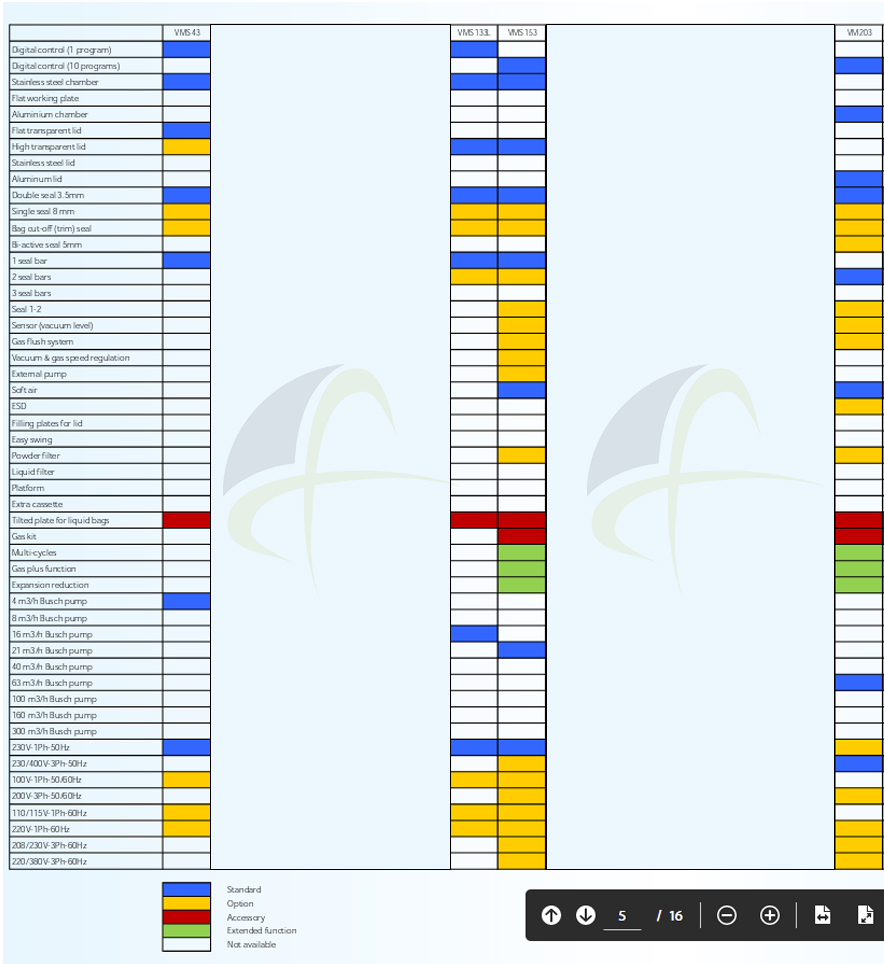

- Click “i” button in table for specifications.

- Open Full Specification Sheet

Audion Vacuum Chambers

Table Top Vacuum Chamber

VMS43Table Top Vacuum Chamber (VMS43)

| Product | Audionvac VMS 43 |

| Seal length | 270 mm |

| Seal width | 3,5 mm double seal |

| Effective chamber size (LxWxH) | 270 x 310 x 85 mm |

| Type of machine | Vacuum chamber |

| Model | Table |

| Covering | Stainless Steel |

| Pump capacity | 4 m3/h Busch |

| Pedal operated | No |

| Type of film | PA/PE, Vacuum Bags |

| Thickness of film | 2 x 150 micron |

| Type of package | Bag |

| Type of product | Granulate, Powder, Solid |

| Machine cycle | 25-60 sec |

| Power | 0,30 kW |

| Voltage | 230V-1-50Hz |

| Weight | 26 kg |

| Machine dimensions | 450 x 355 x 305 |

Audion Vacuum Chambers

Table Top Vacuum Chamber

VMS133Table Top Vacuum Chamber (VMS133)

| Product | Audionvac VMS 133 |

| Seal length | 410 mm |

| Seal width | 3,5 mm double seal |

| Effective chamber size (LxWxH) | 410 x 370 x 180 mm |

| Type of machine | Vacuum chamber |

| Model | Table |

| Covering | Stainless Steel |

| Pump capacity | 16 m3/h Busch pump |

| Pedal operated | No |

| Type of film | PA/PE, Vacuum Bags |

| Thickness of film | 2 x 150 micron |

| Type of package | Bag |

| Type of product | Fluid, Granulate, Powder, Solid |

| Machine cycle | 20-40 sec |

| Power | 0,55 kW |

| Voltage | 230V-1-50Hz |

| Weight | 58 kg |

| Machine dimensions | 530 x 490 x 440 mm |

Audion Vacuum Chambers

Table Top Vacuum Chamber

VMS153Table Top Vacuum Chamber (VMS153)

| Product | Audionvac VMS 153 |

| Seal length | 410 mm |

| Seal width | 3,5 mm double seal |

| Effective chamber size (LxWxH) | 410 x 370 x 180 mm |

| Type of machine | Vacuum chamber |

| Model | Table |

| Covering | Stainless Steel |

| Pump capacity | 21 m3/h Busch pump |

| Pedal operated | No |

| Type of film | PA/PE, Vacuum Bags |

| Thickness of film | 2 x 150 micron |

| Type of package | Bag |

| Type of product | Granulate, Powder, Solid |

| Machine cycle | 15-35 sec |

| Power | 0,75 – 1,0 kW |

| Voltage | 230V-1-50Hz |

| Weight | 64 kg |

| Machine dimensions | 530 x 490 x 440 mm |

| Transport weight | 72 kg |

| Transport size | 720 x 580 x 650 mm |

| Number of gas nozzles (optional) | 2 |

Audion Vacuum Chambers

Floor Standing Vacuum Chamber

VM203Floor Standing Vacuum Chamber (VM203)

| Product | Audionvac VM 203 |

| Seal length | 510 mm |

| Seal width | 3,5 mm double seal |

| Effective chamber size (LxWxH) | 500 x 510 x 230 mm |

| Type of machine | Vacuum chamber |

| Model | Floor |

| Covering | Stainless Steel |

| Pump capacity | 63 m3/h Busch pump |

| Pedal operated | No |

| Type of film | PA/PE, Vacuum Bags |

| Thickness of film | 2 x 150 micron |

| Type of package | Bag |

| Type of product | Granulate, Powder, Solid |

| Machine cycle | 15 – 40 sec |

| Power | 2,4 – 3,5 kW |

| Voltage | 400V-3-50Hz |

| Weight | 163 kg |

| Machine dimensions | 695 x 682 x 1060 mm |

| Number of gas nozzles (optional) | 3 per sealing bar |

Description

Audion Vacuum Chambers

Main reasons to vacuum pack food products ?

- Extend shelf life

- Improve food safety

- Optimize food storage and portion control

- HACCP compatible

- Must for sous vide cooking

Table Top Vacuum Chamber (VMS43)

The VMS 43 is the smallest vacuum packing machine of the AudionVac range. This ergonomic compact vacuum packing machine is equipped with a high quality Busch pump for professional usage. The body is constructed in a way that it will simplify your cleaning process.

>Open Full Specification Sheet<

Benefits

- Standard time control

- Busch vacuum pump

- Maintenance friendly and easy to clean construction

- Made from high quality materials

- Standard double seal

- Standard with a flat transparent lid

- Standard with 1 program memory

- Easy to operate with clear display

- Stainless steel chamber

- Standard equipped with 230-1-50 power supply

Options

- Cut-off seal, to easily tear off the residual plastic.

- Sensor control, constant, guaranteed end vacuum

- High transparent lid, increase your capacity and flexibility

- Inclined plate for 1 silicone holder

Markets

- Meat & Poultry industry

- Food processing

- Direct marketing

- Non-food industry

- Electronics

Table Top Vacuum Chamber (VMS133)

Table top vacuum packaging machine. High quality 16 m3/h Busch pump, richly equipped as standard. Easy to use: plug and play, fast and secure. The VMS 133 is simple to use with just one programme to operate.

>Open Full Specification Sheet<

Benefits

- Standard time control

- Busch vacuum pump

- Maintenance friendly and easy to clean construction

- Made from high quality materials

- Standard double seal

- Standard with 1 program memory

- Easy to operate with digital display

- Stainless steel chamber

- High transparent lid which increase your capacity and flexibility

- Standard equipped with 230-1-50 power supply

Options

- 2 seal bars front and back, double your packing capacity

- Inclined plate for 2 silicone holders

- Wide seal 8 mm

- Cut-off seal, to easily tear off the residual plastic.

- Sensor control, constant, guaranteed end vacuum

- Inclined plate for 1 silicone holder

- Power supply: 110/115-1-60 / 220-1-60 / 1001-1-50/60

Markets

- Meat & Poultry industry

- Food processing

- Direct marketing

- Non-food industry

- Electronics

Table Top Vacuum Chamber (VMS153)

The VMS 153 machine has 10 programmes and which are controlled by a digital control panel. This includes a ‘soft air’ option which enables fragile (fish, potato chips) and sharp (T-Bone steaks) items to be vacuum packed without causing damage. The VMS 153 has an effective chamber size of 410mm x 370 mm and the highest pump capacity out of our desktop offering at 21 m3/h, it also has a 3.5mm double seal positioned to seal the top of the bag.

>Open Full Specification Sheet<

Benefits

- Standard time control

- Standard soft air to vacuum seal sharp products

- Busch vacuum pump

- Maintenance friendly and easy to clean construction

- Made from high quality materials

- Standard double seal

- Standard digital control panel with 10 program memory

- Easy to operate with digital display

- Stainless steel chamber

- High transparent lid which increase your capacity and flexibility

- Standard equipped with 230-1-50 power supply

Options

- 2 seal bars front and back, double your packing capacity

- Inclined plate for 2 silicone holders

- Inclined plate for 1 silicone holder

- Gas flush, Gas flush, modifies atmosphere packaging (MAP)

- Gas flush special, gas flush + bag holder + gas in chamber. Prevents the bag to be blown away during gas (MAP) injection.

- Wide seal 8 mm

- Cut-off seal, to easily tear off the residual plastic.

- 1-2 cut-off seal, same as cut-off seal but in addition with 1-2 cut-off seal the time and settings of the seal and cutting wire can be managed separately.

- Sensor control, constant, guaranteed end vacuum

Markets

- Meat & Poultry industry

- Food processing

- Direct marketing

- Non-food industry

- Electronics

Floor Standing Vacuum Chamber (VM203)

The AudionVac VM 203 is a medium size floor standing vacuum packaging machine. This vacuum packaging machine has a strong solid aluminum vacuum chamber with an aluminum lid. The sight glass in the lid gives you a good overview of your product during your packing process.

>Open Full Specification Sheet<

Benefits

- Standard time control

- Standard soft air to vacuum seal sharp products

- Busch vacuum pump

- Standard double seal

- Maintenance friendly and easy to clean construction

- High quality materials

- Standard 2 seal bars left and right

- Standard with 10 program memory

- Easy to operate with digital display

- Aluminium vacuum chamber

- Aluminium lid with sight glass

Options

- ESD (Electrostatic Discharge ) to pack electrostatic products such as wafers, chips, motherboards and prints. When this occurs during the vacuum packaging cycle, it can cause damage to the product. The Audion ESD technology prevents this.

- Gas flush, modifies atmosphere packaging (MAP)

- Wide seal 10 mm

- Aluminum end blocks, for heavy duty packaging. Ensure an efficient and durable vacuum packaging process under the most extreme conditions.

- Aluminum end blocks for bi-active, for heavy duty packaging. Ensure an efficient and durable vacuum packaging process under the most extreme conditions.

- Bi-active seal, is recommend to use when vacuum sealing aluminum or thicker bags.

- External pump

- Cut-off seal, to easily tear off the residual plastic.

- 1-2 cut off seal, same as cut-off seal but in addition with 1-2 cut-off seal the time and settings of the seal and cutting wire can be managed separately.

- Sensor control, constant, guaranteed end vacuum

- Validatable

- Calibration

Markets

- Electronics & components

- Medical & pharma & High-Tec

- Meat industry

- Food processing

- Direct marketing

- Non-food industry