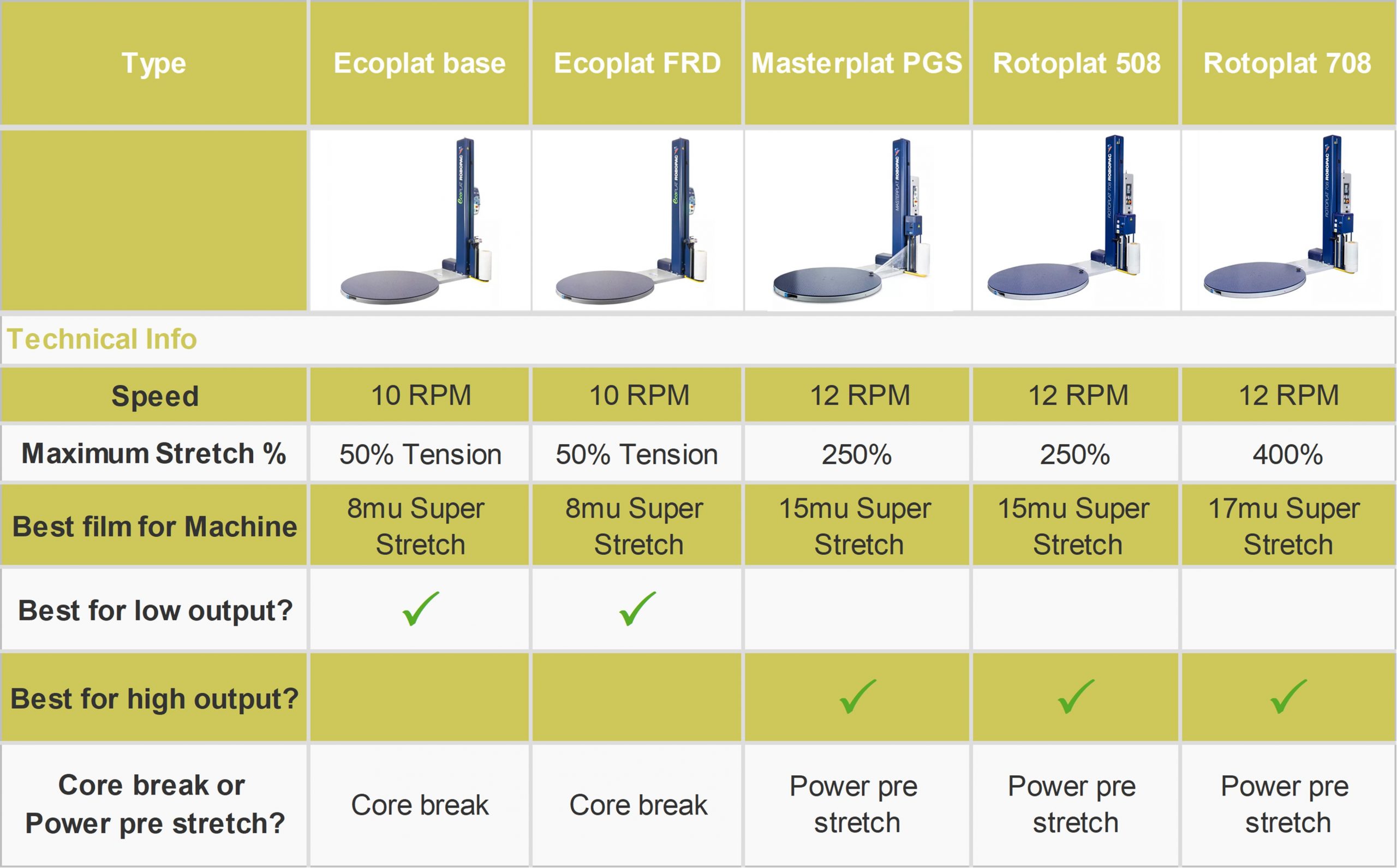

Pallet Stretch Wrapping Machines

From: £0.00

- Pallet Stretch Wrapping Machines for high volume use.

- Standard and low profile machines available.

- Core break system – 1 roller and uses the pallet to pull and stretch the film

- Power pre stretch – 2 rollers and a motor for power to pre stretch the film before leaving the carriage (extra tension can be applied after pre stretching)

- Videos and Brochures available in description.

Pallet Stretch Wrapping Machines

Ecoplat Plus

ECOPLATPLUSEcoplat Plus & Ecoplat Plus FRD

- The Ecoplat Plus or Ecoplat Plus FRD are perfect for businesses moving from hand pallet wrapping to an automated alternative.

- The most economical options in pallet wrapping machines.

- Easy-to-use controls, useful for organisations first introducing this type of technology.

- These machines have a 1650mm turntable, with 2000kg capacity and a 2200mm wrap height, as well as an indexed stop position and soft start for additional safety.

The Ecoplat plus base is an entry-level machine that has all the basic controls you need for quick and easy pallet wrapping.

Pallet Stretch Wrapping Machines

Ecoplat Plus FRD

ECOPLATPLUSFRDEcoplat Plus & Ecoplat Plus FRD

- The Ecoplat Plus or Ecoplat Plus FRD are perfect for businesses moving from hand pallet wrapping to an automated alternative.

- The most economical options in pallet wrapping machines.

- Easy-to-use controls, useful for organisations first introducing this type of technology.

- These machines have a 1650mm turntable, with 2000kg capacity and a 2200mm wrap height, as well as an indexed stop position and soft start for additional safety.

The Ecoplat plus FRD has a control panel with an LED display and uses a manual programming system so you can choose exactly how you want the pallet to be wrapped.

Pallet Stretch Wrapping Machines

Masterplat Plus PGS

MASTERPLATPLUSMasterplat Plus PGS

- Masterplat Plus PGS is designed using the best features from the Ecoplat range with the performance of Rotoplat508 & Rotoplat708.

- Excellent compromise between economic savings and performance

- Pallet stabilization

- Ease of use thanks to the user friendly panel

- The PGS film delivery device is equipped with a powered fixed gear (250%) pre-stretch system.

- A wide range of additional gear sets can also be purchased (150%-200-300%).

Pallet Stretch Wrapping Machines

Rotoplat 508 PDS

ROTOPLAT508PDSRotoplat 508PDS

- Ideal for organisations that are looking for an advanced pallet wrapping machine, or to upgrade the existing set up.

- These machines are the best in pallet wrapping technology, they can be adjusted in many ways to wrap even the most awkward of pallets.

- The Rotoplat machines come with a 1650mm turntable and 2200mm wrap height as standard.

- All Rotoplat machines have a 2000kg turntable capacity.

Rotoplat 508 has a PDS carriage with dual pre-stretch rollers controlled via the control panel. Pre-stretch system is fixed at 250%. “Stretch Control” control activates the electromagnetic clutch positioned on the first roller.

The Rotoplat machines are controlled by a high performance 7-inch colour touch screen with icons. This user-friendly graphical interface allows an easy and immediate use of all available functions. The control panel is the brain of Rotoplat, here lies the heart of the machine and technology "Robopac is Cube Technology".

The features that are adjustable from the control panel include:

- Turntable rotation speed

- Upward/downward spool carriage speed

- Film tensioning

- Force to load for upward and downward

- Pre-stretch ratio

- Upward/downward pre-stretch setting

- Bottom wrappings

- Top wrappings

- Wrapping start point

- Photocell sensing delay

Pallet Stretch Wrapping Machines

Rotoplat 708 PVS

ROTOPLAT708PVSRotoplat 708PVS

- Ideal for organisations that are looking for an advanced pallet wrapping machine, or to upgrade the existing set up.

- These machines are the best in pallet wrapping technology, they can be adjusted in many ways to wrap even the most awkward of pallets.

- The Rotoplat machines come with a 1650mm turntable and 2200mm wrap height as standard.

- All Rotoplat machines have a 2000kg turntable capacity.

Rotoplat 708 has a PVS carriage with a powered stretch system controlled by two independent motors. Stretch ratio adjustable from panel board from 150% up to 400%. Force to the load controlled by patented electronic device and adjustable from panel board.

The Rotoplat machines are controlled by a high performance 7-inch colour touch screen with icons. This user-friendly graphical interface allows an easy and immediate use of all available functions. The control panel is the brain of Rotoplat, here lies the heart of the machine and technology "Robopac is Cube Technology".

The features that are adjustable from the control panel include:

- Turntable rotation speed

- Upward/downward spool carriage speed

- Film tensioning

- Force to load for upward and downward

- Pre-stretch ratio

- Upward/downward pre-stretch setting

- Bottom wrappings

- Top wrappings

- Wrapping start point

- Photocell sensing delay

Pallet Stretch Wrapping Machines

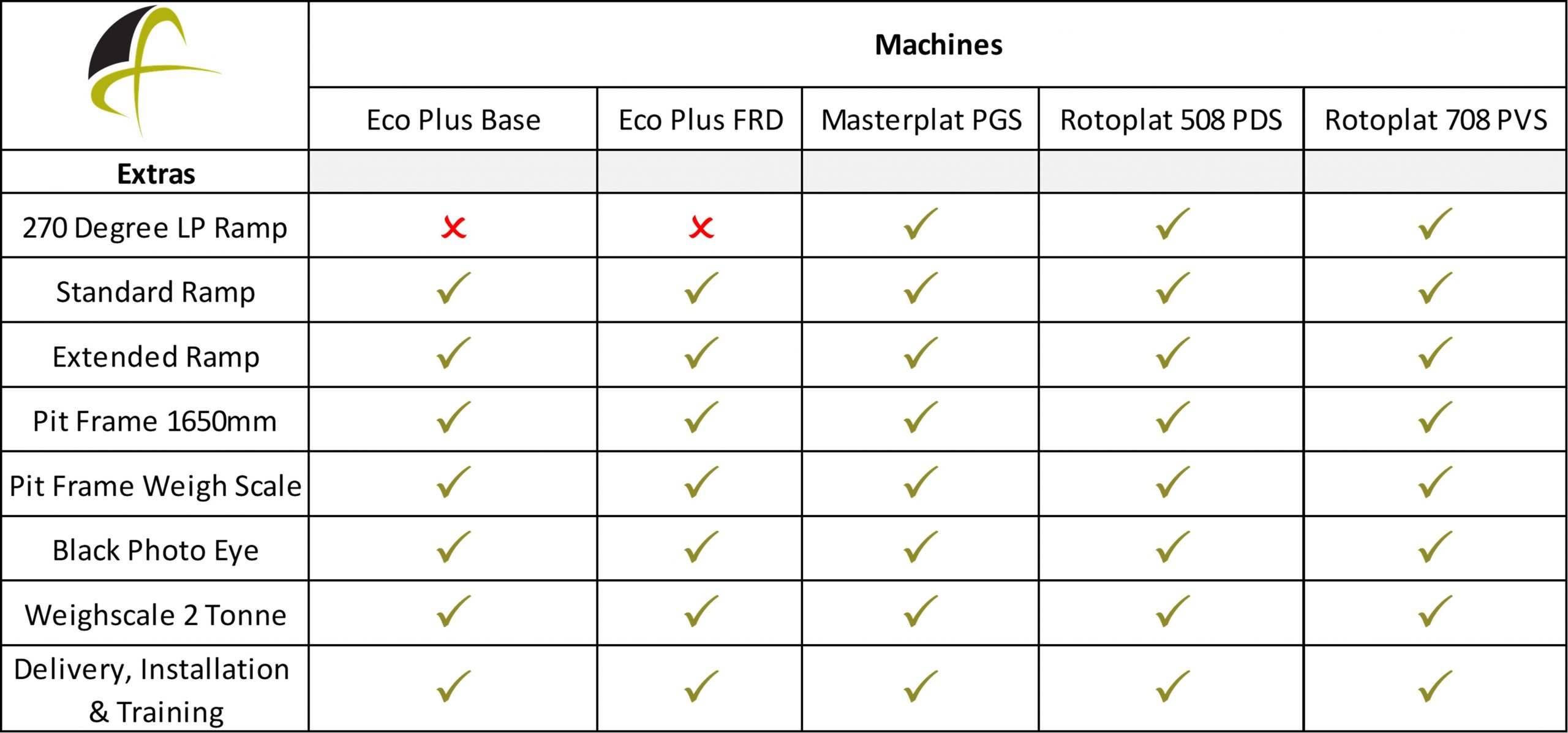

Optional Extras:

Ecoplat Plus & Ecoplat Plus FRD

- The Ecoplat Plus or Ecoplat Plus FRD are perfect for businesses moving from hand pallet wrapping to an automated alternative.

- The most economical options in pallet wrapping machines.

- Easy-to-use controls, useful for organisations first introducing this type of technology.

- These machines have a 1650mm turntable, with 2000kg capacity and a 2200mm wrap height, as well as an indexed stop position and soft start for additional safety.

Masterplat Plus PGS

- Masterplat Plus PGS is designed using the best features from the Ecoplat range with the performance of Rotoplat508 & Rotoplat708.

- Excellent compromise between economic savings and performance

- Pallet stabilization

- Ease of use thanks to the user friendly panel

- The PGS film delivery device is equipped with a powered fixed gear (250%) pre-stretch system.

- A wide range of additional gear sets can also be purchased (150%-200-300%).

Rotoplat 508PDS

- Ideal for organisations that are looking for an advanced pallet wrapping machine, or to upgrade the existing set up.

- These machines are the best in pallet wrapping technology, they can be adjusted in many ways to wrap even the most awkward of pallets.

- The Rotoplat machines come with a 1650mm turntable and 2200mm wrap height as standard.

- All Rotoplat machines have a 2000kg turntable capacity.

- Turntable rotation speed

- Upward/downward spool carriage speed

- Film tensioning

- Force to load for upward and downward

- Pre-stretch ratio

- Upward/downward pre-stretch setting

- Bottom wrappings

- Top wrappings

- Wrapping start point

- Photocell sensing delay

Rotoplat 708PVS

- Ideal for organisations that are looking for an advanced pallet wrapping machine, or to upgrade the existing set up.

- These machines are the best in pallet wrapping technology, they can be adjusted in many ways to wrap even the most awkward of pallets.

- The Rotoplat machines come with a 1650mm turntable and 2200mm wrap height as standard.

- All Rotoplat machines have a 2000kg turntable capacity.

- Turntable rotation speed

- Upward/downward spool carriage speed

- Film tensioning

- Force to load for upward and downward

- Pre-stretch ratio

- Upward/downward pre-stretch setting

- Bottom wrappings

- Top wrappings

- Wrapping start point

- Photocell sensing delay

Optional Extras:

270° Degree Low Profile Ramp

- 270° ramp for easy loading.

- Save space thanks to the reduced dimensions

- High flexibility of loading thanks to the possibility of access from every side

- Reduced thickness to avoid frequent accidental bumps with the fork of the forklift truck

- CANNOT be used with Ecoplat Plus Base & Ecoplat Plus FRD

Ramps (Standard & Extended)

- Ramps for easy loading with hand pallet truck

- 1650mm ramps

- Standard = 1600mm L X 400mm W

- Extended = 2000mm L X 400mm W

Pit Frame - 1650mm

- Pit Frame - 1650mm forms the outline of a pallet wrapping machine in an area of the orgainsations choosing.

- Can be added to existing operations, as long as there is the capacity to create an underground imprint to position the frame within.

- The Pit Frame allows the machine to be positioned slightly below ground level, creating a flat surface for pallets to be moved onto the turntable.

Pit Frame Installation

- Pit frame is made from 80 x 6 steel bar. This is fabricated into the “key hole” shape complete with strengthening bars on the inside to maintain shape whilst casting into concrete.

- Allow a space of at least 400mm between the back of the Pit frame and any obstruction to allow for the over hang of the control panel.

- To fit frame into concrete proceed as follows:

- Dig out concrete approximately 250mm larger than frame.

- Place frame in position required with top edge of frame at floor level and strengthening bars on the bottom.

- When satisfied that frame is in correct position, back fill with concrete to floor level outside frame ensuring 83mm deep inside frame. Check all dimensions as drawing and if correct, allow the concrete to set.

Pit Frame Technical Drawing Sheet

Pit Frame Technical Drawing Sheet

Pit Frame (for Weigh Scale)

- Pit Frame (for Weigh Scale) forms the outline of a pallet wrapping machine in an area of the orgainsations choosing.

- Can be added to existing operations, as long as there is the capacity to create an underground imprint to position the frame within.

- The Pit Frame allows the machine to be positioned slightly below ground level, creating a flat surface for pallets to be moved onto the turntable.

Pit Frame Installation

- Pit frame is made from 80 x 6 steel bar. This is fabricated into the “key hole” shape complete with strengthening bars on the inside to maintain shape whilst casting into concrete.

- Allow a space of at least 400mm between the back of the Pit frame and any obstruction to allow for the over hang of the control panel.

- To fit frame into concrete proceed as follows:

- Dig out concrete approximately 250mm larger than frame.

- Place frame in position required with top edge of frame at floor level and strengthening bars on the bottom.

- When satisfied that frame is in correct position, back fill with concrete to floor level outside frame ensuring 83mm deep inside frame. Check all dimensions as drawing and if correct, allow the concrete to set.

Black Photo Eye

- Black Photo Eye can only be ordered with a stretch wrapping machine

- To be used when wrapping pallets with black or silver products

- Black photo sensor for detection of black pallets.

- Standard sensors will often see a black pallet as a hole and not detect it.

- Please note that this is related to the colour of the items you are packing not the colour of the film.

Digital Weigh Scale (2 tonne)

- For loads up to 2 tonne

- Placed underneath turntable to give digital weight reading

| Max load weight | kg | 1200 std. 2000 opt. (Ø1500) / 2000 std. 2500 opt. (Ø1650-Ø1800) |

| Sensibility | ±0,2 | |

| Integrated printer | opt. | |

| Compatibility | Ecoplat Plus (Ø1500) / Ecoplat Plus, Masterplat Plus, Rotoplat, (Ø1650) / Masterplat Plus, Rotoplat (Ø1800) | |

| Power supply voltage | V | 110-240 V (1Ph) |

| Power supply frequency | Hz | 50/60 |

Delivery, Installation & Training

- Delivery to a UK address (some UK postcodes may incur an additional delivery cost, please check)

Installation of the machine by our engineer

Installation of the machine by our engineer- 30 minutes training on how to use the machine

- Installation & training approx. 2 - 4 weeks

Pallet Stretch Wrapping Machines

270 Degree Low Profile Ramp

270DLPRAMP

Pallet Stretch Wrapping Machines

Standard Ramp

STANDRAMP

Pallet Stretch Wrapping Machines

Extended Ramp

EXTRAMP

Pallet Stretch Wrapping Machines

Pit Frame - 1650mm

PITFR1650Pit Frame Installation

- Allow a space of at least 400mm between the back of the Pit frame and any obstruction to allow for the over hang of the control panel.

Pit frame is made from 80 x 6 steel bar. This is fabricated into the “key hole” shape complete with strengthening bars on the inside to maintain shape whilst casting into concrete.

To fit frame into concrete proceed as follows:

Dig out concrete approximately 250mm larger than frame.

Place frame in position required with top edge of frame at floor level and strengthening bars on the bottom.

When satisfied that frame is in correct position, back fill with concrete to floor level outside frame ensuring 83mm deep inside frame. Check all dimensions as drawing and if correct, allow the concrete to set.

Pallet Stretch Wrapping Machines

Pit Frame (for Weigh Scale)

PITFRWSCALEPit Frame Installation

- Allow a space of at least 400mm between the back of the Pit frame and any obstruction to allow for the over hang of the control panel.

Pit frame is made from 80 x 6 steel bar. This is fabricated into the “key hole” shape complete with strengthening bars on the inside to maintain shape whilst casting into concrete.

To fit frame into concrete proceed as follows:

Dig out concrete approximately 250mm larger than frame.

Place frame in position required with top edge of frame at floor level and strengthening bars on the bottom.

When satisfied that frame is in correct position, back fill with concrete to floor level outside frame ensuring 83mm deep inside frame. Check all dimensions as drawing and if correct, allow the concrete to set.

Pallet Stretch Wrapping Machines

Black Photo Eye

BLPHOTOEYE

Pallet Stretch Wrapping Machines

Digital Weigh Scale (2 tonne)

DWS2T| Max load weight | kg | 1200 std. 2000 opt. (Ø1500) / 2000 std. 2500 opt. (Ø1650-Ø1800) |

| Sensibility | ±0,2 | |

| Integrated printer | opt. | |

| Compatibility | Ecoplat Plus (Ø1500) / Ecoplat Plus, Masterplat Plus, Rotoplat, (Ø1650) / Masterplat Plus, Rotoplat (Ø1800) | |

| Power supply voltage | V | 110-240 V (1Ph) |

| Power supply frequency | Hz | 50/60 |

Pallet Stretch Wrapping Machines

Delivery, Installation & Training

DELINSTATRAIN

Description

Ecoplat Plus & Ecoplat Plus FRD

- The Ecoplat Plus or Ecoplat Plus FRD are perfect for businesses moving from hand pallet wrapping to an automated alternative.

- The most economical options in pallet wrapping machines.

- Easy-to-use controls, useful for organisations first introducing this type of technology.

- These machines have a 1650mm turntable, with 2000kg capacity and a 2200mm wrap height, as well as an indexed stop position and soft start for additional safety.

The Ecoplat plus base is an entry-level machine that has all the basic controls you need for quick and easy pallet wrapping.

The Ecoplat plus FRD has a control panel with an LED display and uses a manual programming system so you can choose exactly how you want the pallet to be wrapped.

Masterplat Plus PGS

- Masterplat Plus PGS is designed using the best features from the Ecoplat range with the performance of Rotoplat508 & Rotoplat708.

- Excellent compromise between economic savings and performance

- Pallet stabilization

- Ease of use thanks to the user friendly panel

- The PGS film delivery device is equipped with a powered fixed gear (250%) pre-stretch system.

- A wide range of additional gear sets can also be purchased (150%-200-300%).

Rotoplat 508PDS

- Ideal for organisations that are looking for an advanced pallet wrapping machine, or to upgrade the existing set up.

- These machines are the best in pallet wrapping technology, they can be adjusted in many ways to wrap even the most awkward of pallets.

- The Rotoplat machines come with a 1650mm turntable and 2200mm wrap height as standard.

- All Rotoplat machines have a 2000kg turntable capacity.

Rotoplat 508 has a PDS carriage with dual pre-stretch rollers controlled via the control panel. Pre-stretch system is fixed at 250%. “Stretch Control” control activates the electromagnetic clutch positioned on the first roller.

The Rotoplat machines are controlled by a high performance 7-inch colour touch screen with icons. This user-friendly graphical interface allows an easy and immediate use of all available functions. The control panel is the brain of Rotoplat, here lies the heart of the machine and technology “Robopac is Cube Technology”.

The features that are adjustable from the control panel include:

- Turntable rotation speed

- Upward/downward spool carriage speed

- Film tensioning

- Force to load for upward and downward

- Pre-stretch ratio

- Upward/downward pre-stretch setting

- Bottom wrappings

- Top wrappings

- Wrapping start point

- Photocell sensing delay

Rotoplat 708PVS

- Ideal for organisations that are looking for an advanced pallet wrapping machine, or to upgrade the existing set up.

- These machines are the best in pallet wrapping technology, they can be adjusted in many ways to wrap even the most awkward of pallets.

- The Rotoplat machines come with a 1650mm turntable and 2200mm wrap height as standard.

- All Rotoplat machines have a 2000kg turntable capacity.

Rotoplat 708 has a PVS carriage with a powered stretch system controlled by two independent motors. Stretch ratio adjustable from panel board from 150% up to 400%. Force to the load controlled by patented electronic device and adjustable from panel board.

The Rotoplat machines are controlled by a high performance 7-inch colour touch screen with icons. This user-friendly graphical interface allows an easy and immediate use of all available functions. The control panel is the brain of Rotoplat, here lies the heart of the machine and technology “Robopac is Cube Technology”.

The features that are adjustable from the control panel include:

- Turntable rotation speed

- Upward/downward spool carriage speed

- Film tensioning

- Force to load for upward and downward

- Pre-stretch ratio

- Upward/downward pre-stretch setting

- Bottom wrappings

- Top wrappings

- Wrapping start point

- Photocell sensing delay

Optional Extras:

270° Degree Low Profile Ramp

- 270° ramp for easy loading.

- Save space thanks to the reduced dimensions

- High flexibility of loading thanks to the possibility of access from every side

- Reduced thickness to avoid frequent accidental bumps with the fork of the forklift truck

- CANNOT be used with Ecoplat Plus Base & Ecoplat Plus FRD

Ramps (Standard & Extended)

- Ramps for easy loading with hand pallet truck

- 1650mm ramps

- Standard = 1600mm L X 400mm W

- Extended = 2000mm L X 400mm W

Pit Frame – 1650mm

- Pit Frame – 1650mm forms the outline of a pallet wrapping machine in an area of the orgainsations choosing.

- Can be added to existing operations, as long as there is the capacity to create an underground imprint to position the frame within.

- The Pit Frame allows the machine to be positioned slightly below ground level, creating a flat surface for pallets to be moved onto the turntable.

Pit Frame Installation

- Pit frame is made from 80 x 6 steel bar. This is fabricated into the “key hole” shape complete with strengthening bars on the inside to maintain shape whilst casting into concrete.

- Allow a space of at least 400mm between the back of the Pit frame and any obstruction to allow for the over hang of the control panel.

- To fit frame into concrete proceed as follows:

- Dig out concrete approximately 250mm larger than frame.

- Place frame in position required with top edge of frame at floor level and strengthening bars on the bottom.

- When satisfied that frame is in correct position, back fill with concrete to floor level outside frame ensuring 83mm deep inside frame. Check all dimensions as drawing and if correct, allow the concrete to set.

It is important that concrete depth inside frame, relative to the floor is 83mm and flat.

Pit Frame Technical Drawing Sheet

Pit Frame (for Weigh Scale)

- Pit Frame (for Weigh Scale) forms the outline of a pallet wrapping machine in an area of the orgainsations choosing.

- Can be added to existing operations, as long as there is the capacity to create an underground imprint to position the frame within.

- The Pit Frame allows the machine to be positioned slightly below ground level, creating a flat surface for pallets to be moved onto the turntable.

Pit Frame Installation

- Pit frame is made from 80 x 6 steel bar. This is fabricated into the “key hole” shape complete with strengthening bars on the inside to maintain shape whilst casting into concrete.

- Allow a space of at least 400mm between the back of the Pit frame and any obstruction to allow for the over hang of the control panel.

- To fit frame into concrete proceed as follows:

- Dig out concrete approximately 250mm larger than frame.

- Place frame in position required with top edge of frame at floor level and strengthening bars on the bottom.

- When satisfied that frame is in correct position, back fill with concrete to floor level outside frame ensuring 83mm deep inside frame. Check all dimensions as drawing and if correct, allow the concrete to set.

It is important that concrete depth inside frame, relative to the floor is 83mm and flat.

Pit Frame (for Weigh Scale) Technical Drawing Sheet

Black Photo Eye

- Black Photo Eye can only be ordered with a stretch wrapping machine

- To be used when wrapping pallets with black or silver products

- Black photo sensor for detection of black pallets.

- Standard sensors will often see a black pallet as a hole and not detect it.

- Please note that this is related to the colour of the items you are packing not the colour of the film.

Digital Weigh Scale (2 tonne)

- For loads up to 2 tonne

- Placed underneath turntable to give digital weight reading

| Max load weight | kg | 1200 std. 2000 opt. (Ø1500) / 2000 std. 2500 opt. (Ø1650-Ø1800) |

| Sensibility | ±0,2 | |

| Integrated printer | opt. | |

| Compatibility | Ecoplat Plus (Ø1500) / Ecoplat Plus, Masterplat Plus, Rotoplat, (Ø1650) / Masterplat Plus, Rotoplat (Ø1800) | |

| Power supply voltage | V | 110-240 V (1Ph) |

| Power supply frequency | Hz | 50/60 |

Digital Weigh Scale Technical Sheet

Delivery, Installation & Training

- Delivery to a UK address (some UK postcodes may incur an additional delivery cost, please check)

Installation of the machine by our engineer

Installation of the machine by our engineer- 30 minutes training on how to use the machine

- Installation & training approx. 2 – 4 weeks